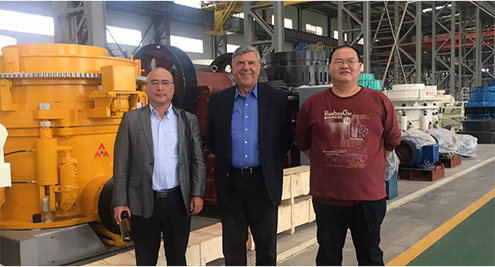

Tailored to customers’ specific requirements, ZHONGXIN’s professional installation engineers offer on-site guidance covering the entire lifecycle of production line setup-including infrastructure construction supervision, equipment installation & commissioning, and full-line trial operation support.

Our professional team delivers targeted training for on-site project technicians, covering core skills such as equipment operation, routine maintenance, and fault identification.

Using original accessories is critical to extending the service life of crushing and screening equipment—they are precisely engineered to match the equipment’s specifications, ensuring optimal compatibility and operational stability.